As people become more and more dependent on electronic products, ensuring electronic raw materials has become one of the national strategies. However, due to a coronavirus, the mass production of mines around the world has been reduced, threatening the tightening of precious metal supply. Now Japan has begun to strengthen its plan to extract gold from waste, and even spread fishing nets to overseas markets to fight for waste electronic products.

The Nikkei News reported that waste electronic products contain not only a large amount of gold and silver, but also industrial metals such as lithium, which is crucial to the manufacture of electric vehicles. In terms of gold alone, Japan's reserves are estimated to be about 6800 tons, surpassing South Africa's underground reserves.

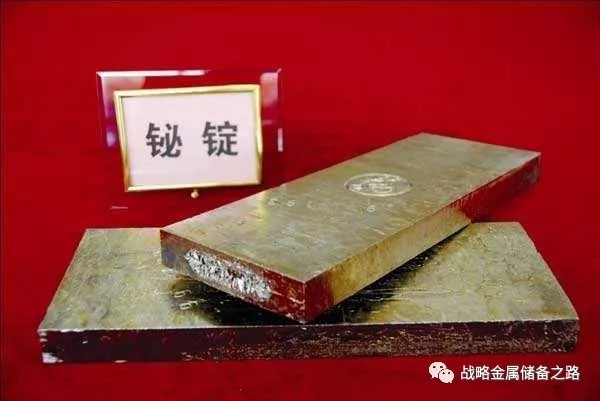

These waste electronic products can extract non-ferrous metals, precious metals and rare metals. Nonferrous metals are relatively ferrous metals. Commonly used nonferrous metals include copper, aluminum, lead, zinc, nickel, tin, antimony, mercury, magnesium and titanium. Rare metals refer to metals with less content or scattered distribution in nature, including lithium, beryllium, niobium, tantalum, rare earth, germanium, gallium, indium, etc. Precious metals are mainly gold, silver and platinum group metals.

Compared with the high content of precious metals in the circuit board, the profit of recovering rare metals is low. The bottleneck includes the cost of classification, disassembly and extraction, and the process involves a lot of manual work. Japan's metal reserve, which is crucial to the production of electric vehicles and high-tech products, is regarded as a national strategy. The National Institute of advanced industrial science and technology is developing an automatic chemical plant that can disassemble electronic products, retrieve and classify specific metals. The new process will increase the output of manual labor by more than 10 times. It is planned to launch a pilot plant before fiscal year 2021.

The EU has also been developing the concept of sustainable recycling for the past four years. Led by Fraunhofer ILT, a research institution in Aachen, Germany, and eight partners from three countries, the strategic goal is to reduce the EU's dependence on natural resources, reduce the import demand for expensive raw materials, and demonstrate new technologies of reverse production.

The technologies used in the new disassembly plant include laser technology, robotics, vision system and information technology, in which the laser can determine the composition of each part and disassemble, weld or cut parts from the plate in a fast and non-contact manner. Through reverse production technology, the country's dependence on raw materials in other regions can be reduced.

In addition to discarded electronic products, second-hand lithium-ion batteries, especially those used in electric vehicles, are another potential wealth of urban mining. At the end of its service life, lithium-ion car batteries can still be used for other purposes, such as household power storage. Multiple batteries can be connected to build a storage system of renewable energy facilities.

Itochu of Japan cooperates with prand and BYD, Chinese pure electric vehicle battery recycling enterprises, and Marubeni, a Japanese trading company, also invests in byton, a Chinese electric vehicle company, to carry out lithium battery reuse business. The original resources will be exhausted one day. In the face of the surge in high-tech demand in the future, waste electronic products and lithium batteries will become important strategic resources in the future.

随着人们对电子产品的依赖度越来越高,确保电子原料成为国家战略之一,但因为一场冠状病毒,让世界各地的矿山量产减少,威胁到贵金属供应趋紧,日本现在开始加大力度从废弃物中提取金属的计划,甚至将渔网撒向海外市场,展开废弃电子产品争夺战。

日经新闻报道,废弃电子产品不仅含有大量的黄金和白银,还含有对制造电动汽车至关重要的锂等工业金属。仅就黄金而言,日本储量估计约为6,800吨,超过南非的地下矿藏。

这些废弃电子产品可以提取有色金属、贵金属、稀有金属。有色金属相对的是黑色金属,常用的有色金属包括铜、铝、铅、锌、镍、锡、锑、汞、镁及钛。稀有金属是指自然界中含量较少或分布稀散的金属,包括锂、铍、铌、钽、稀土、锗、镓、铟等。贵金属主要为金、银和铂族金属。

与电路板中含量高的贵金属相比,回收稀有金属的利润较低,瓶颈包含在分类、拆卸和提取费用,过程涉及大量的手工工作。日本对电动汽车和高科技产品生产至关重要的金属储备视为国家战略,国家先进工业科学技术研究院正在开发能够拆卸电子产品、检索和分类特定金属的自动化工厂,新流程将比手工劳动的产出提高10倍以上,计划在2021财年之前推出一个试验工厂。

欧盟过去四年也一直在开发可持续的回收概念。牵头的是位于德国亚琛的研究机构弗劳恩霍夫激光技术研究所(Fraunhofer ILT),以及来自三个国家的八个合作伙伴参与,战略目标是减少欧盟对自然资源的依赖,减少对昂贵原材料的进口需求,并演示逆向生产的新技术。

新的拆卸工厂采用的技术包括激光技术、机器人技术、视觉系统和信息技术,其中激光可以确定每个零件的组成并以快速、非接触的方式从板上拆焊或切割零件。通过逆向生产技术,可减少国家对其他地区原材料的依赖。

除了废弃电子产品之外,二手锂离子电池,尤其是电动汽车中使用的锂离子电池,是城市采矿业的另一种潜在财富。锂离子汽车电池在使用寿命结束时,仍可用于其他用途,例如家用电力存储,可以连接多个电池来打造可再生能源设施的存储系统。

日本伊藤忠商事与中国的纯电动汽车电池回收企业普兰德、比亚迪合作,日本贸易公司丸红(Marubeni)也投资中国电动汽车公司Byton,展开锂电池再利用业务。原始资源将有耗尽的一天,面对未来的高科技需求暴增,未来废弃电子产品与锂电池将成为重要战略资源。